Environment Environmental Management

Basic Approach

The Mitsubishi Tanabe Pharma Group conducts environmental management, and has formulated Environment & Safety Policy, which set out a basic approach and initiatives for business activities.

We promote activities that consider the environment, safety, and health in line with these guidelines and policies and constantly strive to reduce our environmental impact. We also proactively disclose information on our environmental safety activities to society and promote communication with stakeholders.

- Code of Conduct for the Environment and Safety

- In conformity with the overriding principle that safety is paramount, we strive to prevent accidents occurring at workplaces and to implement adequate precautions and preparations against all contingencies, including occupational accidents and disasters. We also take continuing steps to reduce the impact of our corporate activities on the natural environment and we are fully committed to community environmental conservation activities.

- Environment & Safety Policy

-

Mitsubishi Tanabe Pharma Corporation and its group companies (the “MTPC Group”) aim to be global research-driven pharmaceutical companies that are trusted by society, and actively strive to protect global environment and ensure people’s safety.

- 1We assess our corporate activities for their environmental impact in order to continuously reduce environmental burden.

- 2We give priority to safety considerations for all of our workers to prevent occurrence of occupational accidents.

- 3We set clear targets for our environmental and safety activities, and we effectively maintain and improve our system to achieve such targets.

- 4We pursue activities in compliance with not only laws and regulations relating to environment and safety, but also more rigorous corporate management standards.

- 5We systematically conduct training to enhance each and every employee's awareness on the environment and safety.

- 6We proactively disclose information relating to environment and safety so that we can deepen communication with society.

- 7By proactively participating in and cooperating with environmental management and disaster reduction activities organized by local communities, we prepare against unforeseen contingencies such as accidents and disasters, so as to minimize their impact.

Environmental Compliance

The Group has declared that “We work actively to protect the global environment and strive to realize the Company’s harmonious co-existence with society” as a compliance action policy to be implemented by each employee.

Specifically, in every aspect of our business activities, we will strive to reduce greenhouse gas emissions, promote energy conservation, resource conservation and resource recycling, reduce waste, and participate in and cooperate with local communities in environmental conservation activities. We will work to achieve a sustainable society by transitioning to a carbon-neutral society and a circular economy as well as protecting the global environment.

We will continue to reduce our environmental impact by creating a companywide environment and occupational safety management system, establishing, and sharing goals and targets for environment and safety management, and formulating, implementing, evaluating, and reviewing plans at all offices. We will thoroughly manage environmental and safety risks and take prompt and appropriate actions to deal with any problems that may arise.

In accordance with our environmental and safety policy, we will set voluntary management standards for production and research bases that are stricter than those required by law with regard to water and air pollution, as well as complying with environmental laws and regulations. Additionally, we utilize regular internal audits and other measures to confirm the status of environmental compliance at each of our bases.

Environmental Management Promotion System

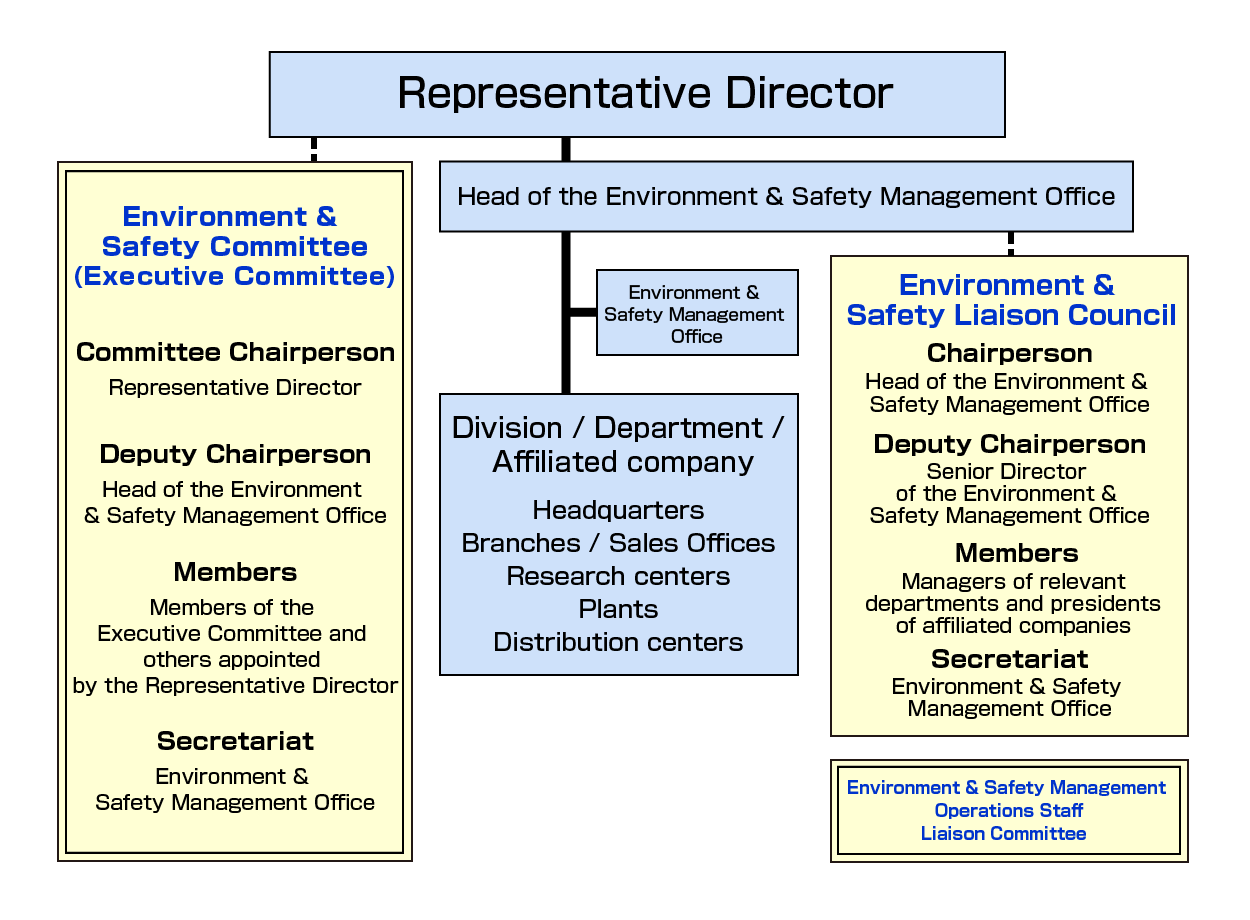

We are moving forward with a system of environmental management with the Representative Director in charge. Chaired by the Representative Director, the Environment & Safety Committee convenes regularly to discuss and make decisions on important environmental and safety issues, medium-to-long-term as well as annual policies, and activity goals.

In addition, the Environment & Safety Liaison Council, which consists of heads of each division and presidents of Group affiliated companies, and is overseen by the Head of the Environment & Safety Management Office, meets regularly. The Council thoroughly discusses and reviews activities related to the environment and safety as well as execution plans and submits important matters and issues related to policy decisions to the Environment & Safety Committee.

Furthermore, we established the Environment & Safety Management Office in the corporate organization as a department that oversees environment and safety matters for the Group as a whole. Through close ties with management and frontline workers, the office supports stronger frontline capabilities and the development of a culture of safety. In this way, the office works to prevent the occurrence or recurrence of accidents related to the environment and safety.

The policies, targets, and plans of the Group with regard to the environment are formulated in conjunction with the Mitsubishi Chemical Group (the MCG Group). We engage in regular exchanges of information within the MCG Group as we undertake environmental activities.

The Mitsubishi Tanabe Pharma Group Environmental Management Promotion Systems

ISO 14001 Certifications

Of the Group’s production bases in Japan and overseas, four bases have obtained ISO 14001 certification. At production and research bases that have not obtained ISO 14001, we are building our own environment management systems in accordance with ISO 14001 and are managing these appropriately.

Bases with ISO 14001 certification

| Company name | Name of base | Year certification first obtained |

|---|---|---|

| Mitsubishi Tanabe Pharma Factory | Onoda Plant | 1998 |

| Yoshitomi Plant | 2001 | |

| Mitsubishi Tanabe Pharma Indonesia | Bandung Plant | 2004 |

| Mitsubishi Tanabe Pharma Korea | Hyangnam Plant | 2014 |

Environmental Audits

The environment management department periodically (Domestically: Annual, Overseas: Biennially) conducts environmental audits at production and research bases in Japan and overseas to confirm matters such as the status of environmental management and compliance, and that its environmental conservation activities are conducted legally and appropriately.

In these audits, we use check sheets, etc., to check the status of compliance with internal rules, and the management status of environment-related facilities (waste storage facilities, wastewater treatment facilities, exhaust gas generation facilities, etc.). We ask that they submit an improvement plan and report to address the matters identified in the audit and confirm their response at the next audit. We ensure the effectiveness of environmental audits at our overseas bases by periodically conducting EHS compliance audits by external specialists who are familiar with the laws and regulations of the countries and regions in which they are located.

In fiscal 2023, environmental audits were conducted at five domestic bases (Yokohama Office, Shonan Office, Onoda Office, Onoda Plant, and Yoshitomi Plant). Overseas, audits were conducted at one base (Mitsubishi Tanabe Pharma Indonesia).

With reference to overseas audits in particular, remote audits have been conducted online since fiscal 2020 due to the spread of COVID-19. This year audits were performed onsite for the first time in four years, with the status of environmental activities confirmed, and initiatives and issues unique to each business location shared.

Priority items checked in audits

- Managerial and operational status of environment-related facilities, etc.

- Status of initiatives to reduce environmental impact

- Status of compliance with environmental laws and regulations and internal rules

- Status of compliance with revisions to regulations, etc. in accordance with changes in PRTR substances

Environmental Education

Aiming for rigorous environmental compliance, the Group plans and implements environmental education and training in accordance with the level of connection to the environment.

Employees in charge of environmental management, work to maintain and improve specialized skills and knowledge about environmental management by proactively obtaining qualifications and taking outside training courses.

In fiscal 2023, we held basic training for new employees and MR, as well as specialist technical training regarding soil contamination for people responsible for environmental management at our bases.

Major training conducted in fiscal 2023

| Training for new employees |

|

|---|---|

| Environmental training for MR |

|

| Environmental laws and regulations training |

|

| Training on the Soil Contamination Countermeasures Act |

|

Status of Environmental Accidents/Violations of Environmental Laws and Regulations

For the seventh consecutive year, the Group had no environmental accidents and no major violations of environmental-related laws and regulations.